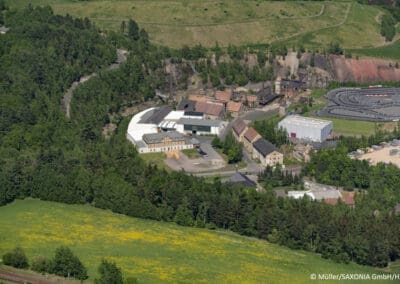

Muldenhütten

The remaining historic and listed metallurgical buildings and their partially preserved technical facilities make the site one of the oldest non-ferrous metallurgy locations still in existence in Germany. The ensemble includes buildings from the late 18th to the early 20th century.

The Pattinson hut and the shaft furnace building are of historical relevance to the recomine project. These buildings are part of the site at Shaft Furnace I of the historic ironworks complex. The mineral building fabric (plaster, mortar), the dust and the floors of both the shaft furnace building and the Pattinson hut are heavily contaminated with pollutants such as As, Pb, Cd, Cu and Zn, which originate from the smelting of Freiberg ores (Darbinjan, 2017).

History

Especially since the first half of the 19th century, Muldenhütten developed into an industrial center in the Freiberg region, from which significant technological developments for the entire metallurgical industry emerged (Albrecht, 1999). At the end of the World War II in 1945, iron and steel production came to a standstill, as did Freiberg mining. Important systems and equipment were dismantled as part of the reparations payments to the Soviet Union. Nevertheless, the production of lead and precious metals was able to start again at the end of 1945.

In 1961, all smelters and mines in the Freiberg area were merged to form the VEB Bergbau- und Hüttenkombinat “Albert Funk” Freiberg. The first major decision was to concentrate lead production in Muldenhütten in the future. For economic reasons, mining in Freiberg and the surrounding area had to be closed in 1969. This meant that lead smelting in Muldenhütten was switched exclusively to secondary raw materials, mainly battery scrap.

The political change in 1990 meant the end of the steelworks combine. In the course of the transformation of the Muldenhütten site, individual production areas were spun off. As a result of the transformation process, a mix of companies from the recycling and metal sectors as well as other innovative industrial and commercial enterprises emerged (Hein, 2010).

Redevelopment and restructuring measures have resulted in the loss of a significant proportion of the historic buildings that once existed. The site at Schachtofen I in the northern part of the Muldenhütten site is an exception, with the historic buildings Schachtofengebäude and Pattinsonhütte.

Area at the Shaft Furnace I

The site at Schachtofen I is the oldest surviving part of the historic ironworks in Muldenhütten. The foundations of some of the buildings date back to the 16th century. The entire area is approx. 2.5 ha in size (Mollée, 2013).

Shaft Furnace Building

The shaft furnace building (= shaft furnace I) was built in 1886/87 in the north-eastern area of the Hüttenhof. The blast furnace forecourt is located to the east of the building, with the slag yard and pelletizing basin to the south in the direction of the Hüttenhof. In 1939, the shaft furnace, which still exists today, was installed during a conversion and the shaft furnace building was extended. The building consists of three floors with the tapping facility on the first floor, the flue gas duct in the middle and the furnace platform on the upper floor. The original shaft furnace still exists and was in operation until 1991. It is a Pilz shaft furnace (Darbinjan, 2017). The shaft furnace building is a listed building and has been a UNESCO World Heritage Site since 2019.

Pattinson Smelter and Zinc Desilvering

The Pattinson Smelter consists of a part of the building in which the Pattinson method was used (the northeast wing) and a part of the building which was used for zinc desilvering (the northwest wing).

The Pattinson smelter was built around 1855/56 as part of the introduction of the Pattinson process. It was initially used to produce pure lead from lead containing precious metals using the Pattinson process. In 1885, the zinc desilvering process according to Parkes was introduced in the northwest wing of the building. In 1886, structural alterations were made to the Pattinson smelter, which led to the size it still has today. The labor-intensive Pattinson process was discontinued in 1921 and a mechanical overhead conveyor was built at the same time (Kolditz, 2009). A hard lead plant was built in 1943. After 1945, the basin and the pumps of the cooling water circuit of shaft furnace I were relocated to the north-east wing of the Pattinson smelter. Zinc desilvering was discontinued in 1969 and hard lead production in 1972 (Kolmschlag, 2010). The Pattinson hut and the shaft furnace building are listed buildings and have been a UNESCO World Heritage Site since 2019.

Projects and activities in Muldenhütten

- Project seminar of Viennese students: Development of ideas for an environmental and cultural center as well as a swimming pool in connection with the industrial ensemble Muldenhütten

- Usage concept, which envisages museum and gastronomic uses in the Pattinson Smelter and zinc desilvering

- Concept for an environmental and cultural center

- Concept of a swimming pool in connection with an industrial ensemble

- Concept for a gastronomic use

Social and cultural potential

Due to the large number of comparable locations available worldwide, Muldenhütten can set standards and serve as a benchmark. Potential re-use concepts have to be developed with respect to the world heritage status of the buildings.

References (in German)

Darbinjan, F. (2017): Bericht Hüttenkomplex Muldenhütten, Schachtofen I, Schadstoffuntersuchung., Verfasser: Gea SAXONIA.

Hein, D. (2010): Freibergs Hüttenwerke Bilder aus Vergangenheit und Gegenwart., Hrsg.: SAXONIA Standortentwicklungs- und -verwaltungsgesellschaft mbH, Freiberg.

Kolditz, C. (2009): Der historische Hüttenstandort Muldenhütten, Erläuterungsbericht zur denkmalpflegerischen Analytik sowie zu konzeptionellen und entwerferischen Ansätzen.

Kolmschlag, F.-P. (2010): Sieben Jahrhunderte Hüttenstandort Muldenhütten., Hrsg.: Muldenhütten Recycling und Umwelttechnik GmbH.

Kowar, R. (2017): Muldenhütten Ein Rückblick in historischen Postkarten., Hrsg.: Muldenhütten Recycling und Umwelttechnik GmbH, Freiberg.

Mollée, R. (2013): Altlastenprojekt SAXONIA 1993 – 2013 eine Retroperspektive., SAXONIA Standortentwicklungs- und -verwaltungsgesellschaft mbH (Hrsg./Verlag), 1. Auflage, Freiberg.

Contact

SAXONIA Site Development and Management Company mbH

Sabine Meißner

+49 3731 39-5026

sabine.meissner@saxonia-freiberg.de

Documents for download (German)

Map of Muldenhuetten

Survey of the shaft furnace SAXONIA GmbH 2008

See on the map

Muldenhütten on Google Maps

Further links (German)

Himmelfahrt Fundgrube with the Muldenhütten hut complex

Shaft furnace building in Muldenhütten

Objects of investigation

- Social and cultural valorization

- Sustainable use of the Pattinson Smelter and the shaft furnace building

- Development and testing of a decontamination of the heritage location

- Testing of the cooperation between heritage preservation, science, SMEs and municipalities

Pollutants

Projects

Social Works

Development sites:

Ehrenfriedersdorf

Freiberg - Davidschacht

Freiberg - Roter Graben

Muldenhütten

Term: 01.01.2020 to 31.10.2022

Analysis of decision-making structures and conflicts and development of a methodological toolkit for transdisciplinary...

Our lead partner:

VeharstGlass

Development sites:

Ehrenfriedersdorf

Freiberg - Davidschacht

Freiberg - Roter Graben

Muldenhütten

Duration: From 01.04.2023 to 31.12.2025

Our lead partner:

LLV Muldenhütten

Development sites:

Muldenhütten

Duration: From 01.07.2023 to 31.12.2025

LLV (learning-teaching-mediation location) Muldenhütten

Our lead partner: