DigiFloat

Digitalization and model predictive control of complex treatment processes using sensor fusion and AI-supported evaluation

Time span

From 01.07.2023 to 30.06.2025

Abbreviation

DigiFloat

Project type

Digitalization generic impulses

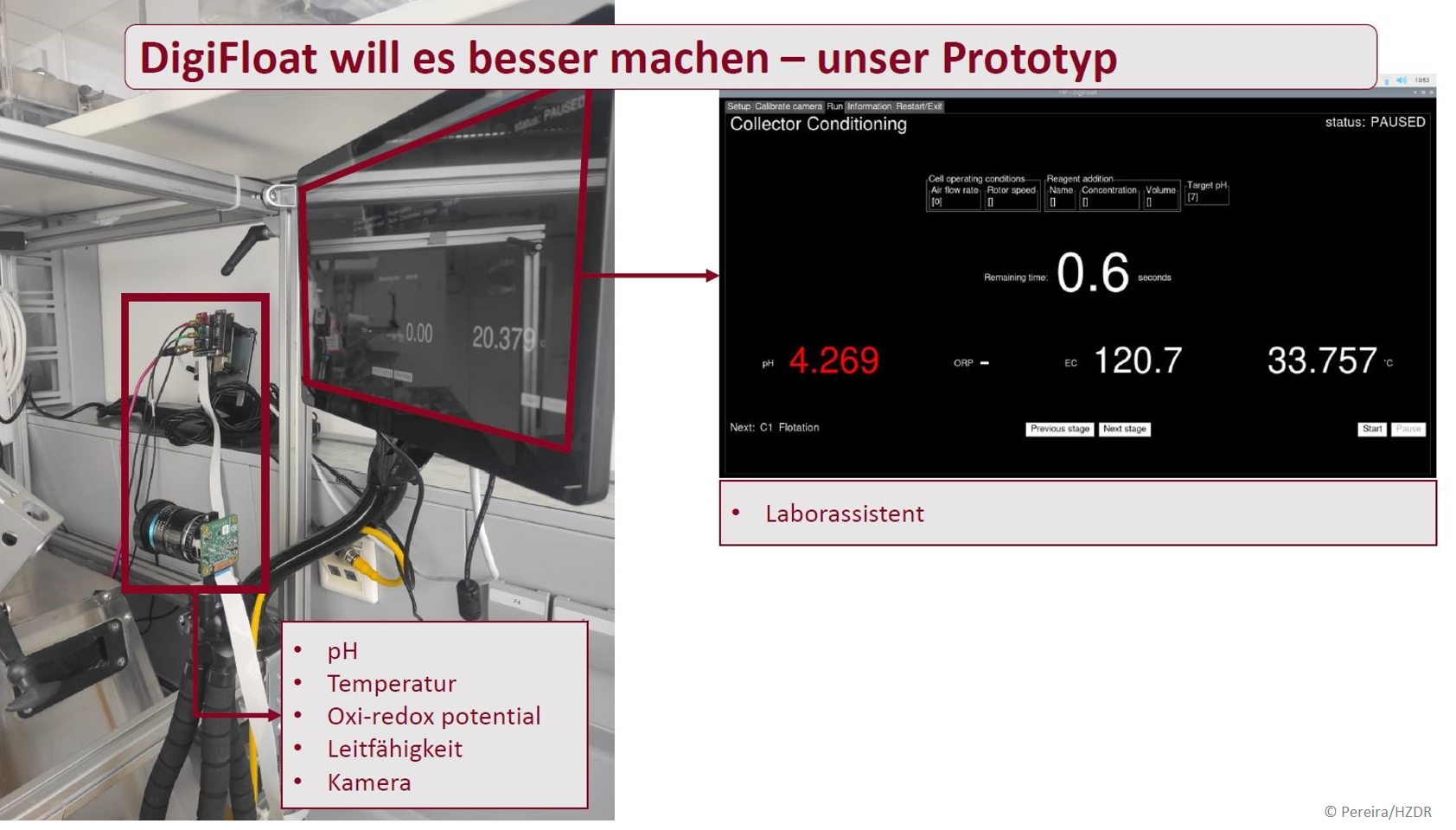

The DigiFloat project aims to provide generic impulses for the optimization of complex treatment processes through digitalization. One example is flotation, a physical-chemical separation process for fine-grained solids, which is important in ore processing, wastewater treatment and recycling.

An important point is the detailed and comprehensive recording of process data. The project aims to expand the possibilities of substance-related sensor technology by establishing a system for the online detection of chemical compositions in complex structures (e.g. foam) in the dynamic process under standard industrial conditions using spectroscopic systems. In addition, the miniaturization of media-contacting sensors will improve the reliability and relevance of the process data, as the invasive measurement technology will have less influence on the process.

The next step in the data flow is recording, validation and evaluation. This is where the project comes in by establishing a data lake that processes the raw data from the new sensors. Together with offline results and information on the use of energy and raw materials, this data is enriched, analyzed and visualized in such a way that multivariate correlations of the complex flotation process become transparent. The result is a system that can use AI-supported data fusion to alert users to any need for action. The system will also demonstrate the function of predictive process control. For this purpose, KPIs are formed from data and information that can be used to dynamically evaluate and control the flotation process. The main objective is therefore to optimize complex processes in terms of yield and efficiency by predicting the process results. At the end of the project, a concept study will be available that summarizes the findings of the individual objectives and describes the scale-up for industrial plants in detail.

Contact

Helmholtz Institute Freiberg for Resource Technology

Dr. Lucas Pereira

+49 351 260447

l.pereira@hzdr.de

Partners

Helmholtz-Institut Freiberg für Ressourcentechnologie

Maelgwyn Mineral Services Limited

Simba-n³

Kurt-Schwabe-Institut für Mess- und Sensortechnik e.V. Meinsberg

Universität Potsdam, Institut für Chemie – Optische Sensorik u. Spektroskopie

SECOPTA analytics GmbH