LiDoVa

Sustainable recovery of vanadium from LD slag

Time span

From 01.01.2023 to 31.12.2025

Abbreviation

LiDoVa

Project type

Sustainable recovery of vanadium from LD slag

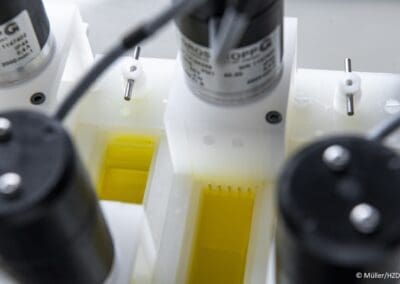

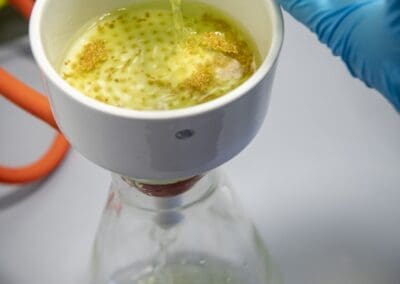

The main objective of LiDoVa is the extraction of 2 high-quality products from LD slags, which are produced in the converter during the further processing of pig iron into steel. These are vanadium (compounds) and construction material for the building materials industry. The project consortium will conduct research on three main pillars: (1) Development and upscaling of a process for the extraction of vanadium and the production of V2O5 and ferrovanadium from LD slag (2) Characterization and valorization of the slag and the residues produced in the process for the production of cement-free building materials based on alkali-activated materials, (3) Economic and, in particular, ecological considerations.

In line with the implementation of this zero-waste concept, this opens up the possibility of using processed LD slag as an alternative to the most important reactive composite materials to date, blast furnace slag and hard coal fly ash, while at the same time recovering vanadium, which is only available to a limited extent worldwide in the required quality, for use in modern energy storage systems, for example.

Development location: Freiberg, Chemnitz, Aue.

Project update

Contact

Helmholtz Institute Freiberg for Resource Technology

Dr. Norman Kelly

+49 351 2604740

n.kelly@hzdr.de

R & D Locations

Resources

V

Partners

Helmholtz-Institut Freiberg für Ressourcentechnologie

TU Chemnitz, Professur Strukturleichtbau und Kunststoffverarbeitung

Nickelhütte Aue GmbH