MemTecPlus

Material Recovery by Flat Membrane Filtration

Time span

From 01.10.2022 to 30.09.2025

Abbreviation

MemTecPlus

Project type

Material Recovery by Flat Membrane Filtration

Goal of the Project MemTecplus is the development of a continuously working membrane filtration system with high chemical and mechanical stability for the treatment of mining waters and the quantitative separation of pollutants and heavy metals and the extraction of rare earths from waters of old mines and spoil heaps bound particulate.

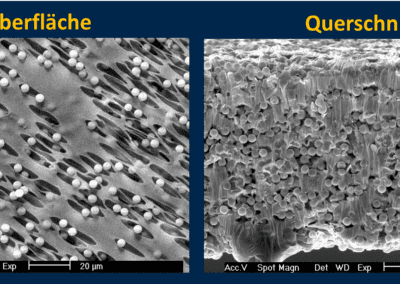

The core of the project is the development of an innovative microporous membrane filter system based on polyvinyl chloride membranes. PVC has not yet been used as a membrane material, but has excellent properties for use as a filter material in the technical sector:

- stability in a wide pH-range

- high resistances

- cost-efficient

- manufacture of pores with an appropriate pore size of 0.5-20 μm by drawing a PVC film filled with particles

For the manufacture of the membranes a cost-efficient, industrial process that allows for a setting of material properties according to the requirements will be developed.

New modular filter units are manufactured by laminating membranes to a drainage textile. These composites are processed to filter pockets, which are hydraulically connected to form stacks.

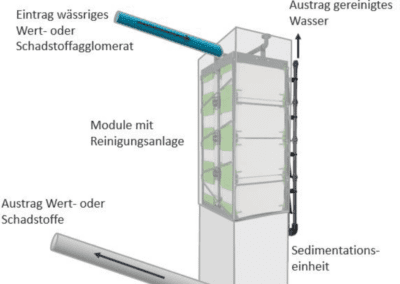

The process engineering combination of newly developed in situ purification processes (mechanical and/or fluidic) with sediment compaction of the precipitation and its continuous discharge means that water purification is coupled with the recovery of valuable substances. For this purpose, it is necessary to precipitate the substances to be separated in an upstream inline process step.

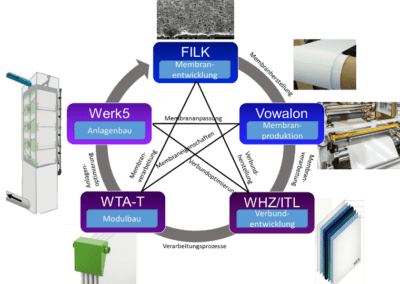

An innovative system concept for microfiltration modules is being developed for the continuous particulate separation of target substances and simultaneous water purification. All production steps from the manufacture of the membranes to module construction can be carried out by companies in the Ore Mountains region. Furthermore, a high global market potential is expected for the filter systems.

Contact

FILK Freiberg Institute

Dr. Kristin Trommer

+49 3731 366-141

kristin.trommer@filkfreiberg.de

Partners

FILK Freiberg Institute gGmbH

G-Werk5 GmbH, Standort Görlitz / Markersdorf

WTA Technologies GmbH

Vowalon Beschichtung GmbH Treuen

Westsächsische Hochschule Zwickau