The Davidschacht Tailing was in operation from 1951 to 1964. It has an area of approx. 6.3 ha and a volume of approx. 760,000 m3. By processing ores from the Freiberg mining area at Davidschacht, mainly residues from wet chemical flotation and finely ground components of Freiberg gneiss were flushed into the tailing.

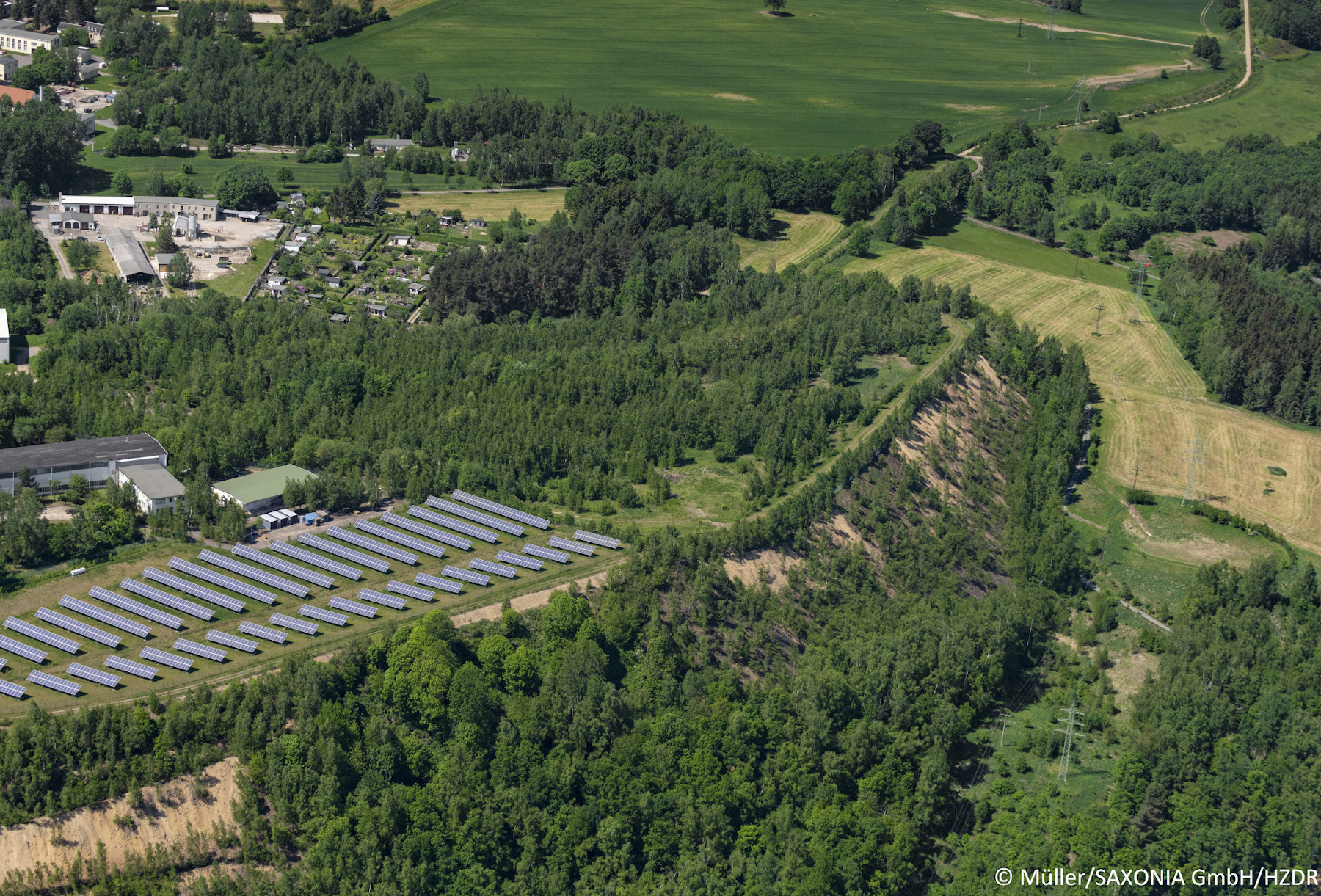

The Davidschacht Tailing belongs to the former Davidschacht mining site together with the Hammerberg Tailing, the Grobbergedamm and the Grobbergehalde David-Richtschacht. The Davidschacht Tailing is located in the northeastern peripheral area of Freiberg, directly on the valley slope to the Freiberger Mulde River. Numerous commercial enterprises shape the image of the Davidschacht location (IBUR, 1995b).